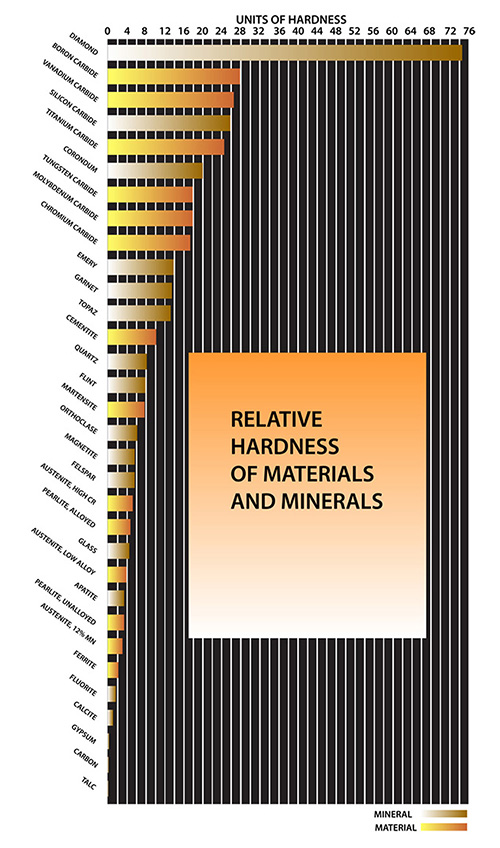

ʻO ka paʻakikī pili o nā mea a me nā minerala

-

- 1. Daimana

- 2. Boron carbide

- 3. Vanadium carbide

- 4. Silicon carbide

- 5. Titanium carbide

- 6. Korundum

- 7. Tungsten carbide

- 8. Molybdenum carbide

- 9. Chromium carbide

- 10.Emery

- 11. Garnet

- 12. Topaza

- 13. ʻO ka Sima

- 14. Kuaha

- 15. Paha

- 16. ʻO Martensite

- 17. ʻO Orthoclass

- 18. Magnetite

- 19. Felspar

- 20. Austenite, CR Kiekie

- 21. Pearlite, Alloyed

- 22. Aniani

- 23. Austenite, Aleki haahaa

- 24. Apatite

- 25. Pearlite, Unliloyed

- 26. Austenite, 12% Mn

- 27. Ferrite

- 28. Fluorite

- 29. Calcite

- 30. ʻO Gypsum

- 31. Kalapona

- 32. Talc

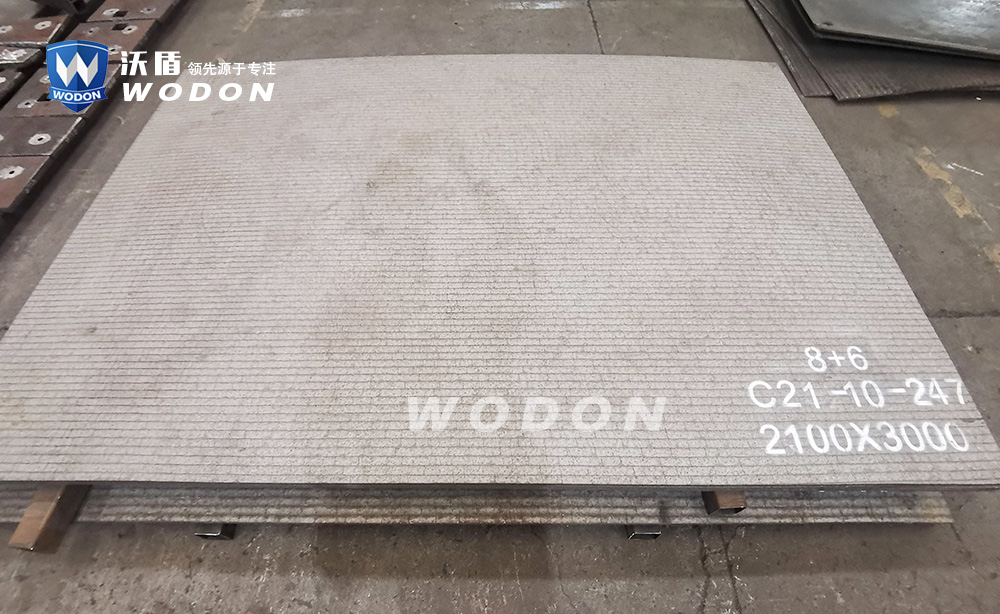

- Wodon He loea i ka hana Chromium carbide overlay wear plate, hoʻohana mākou i ka ʻenehana welding arc submerged i loaʻa nā ʻike Cr hou aʻe mai 25% a 45%. ʻO ka hapa nui o ka carbide ma ka microstructure ma luna o 50% a ʻo ka ʻoi loa o ka paʻakikī o ka ʻāpana paʻakikī ʻo HV1800. aia ka ASTM-G65 ala A ma lalo o 0.16g.

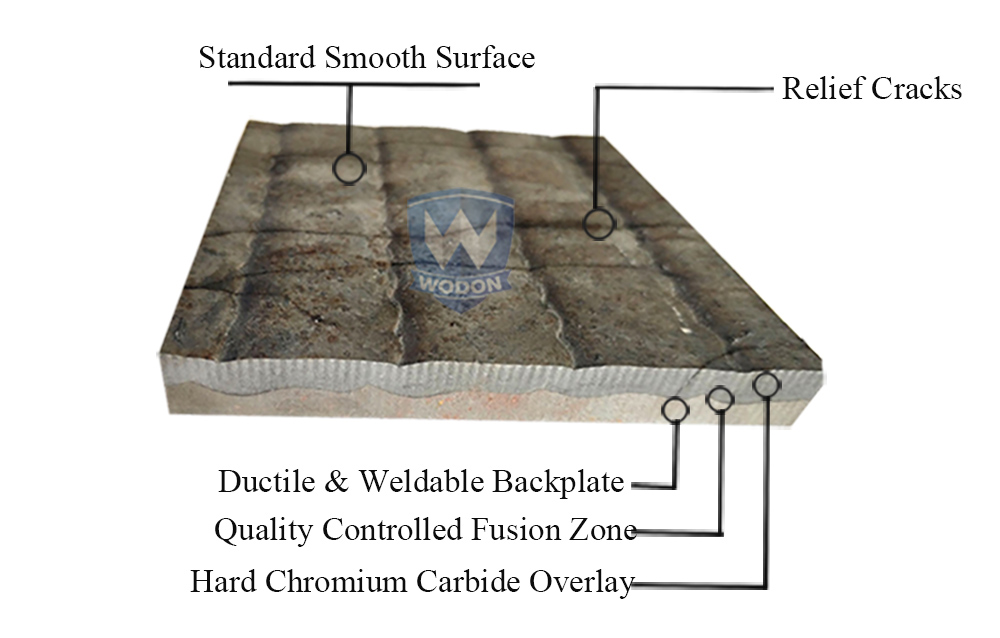

- ʻO ka pā bimetallic Chromium Carbide:

- Kauwaena/Low carbon steel +Anā papa pale pale →Chromium carbide bimetallic pā me ka hoʻopaʻa metala

- (Q235/Q345B + Chromium Carbide overlay →Chromium carbide bimetallic plate by Submerged arc or Open arc welding

- ʻenehana)

- kikoʻī:

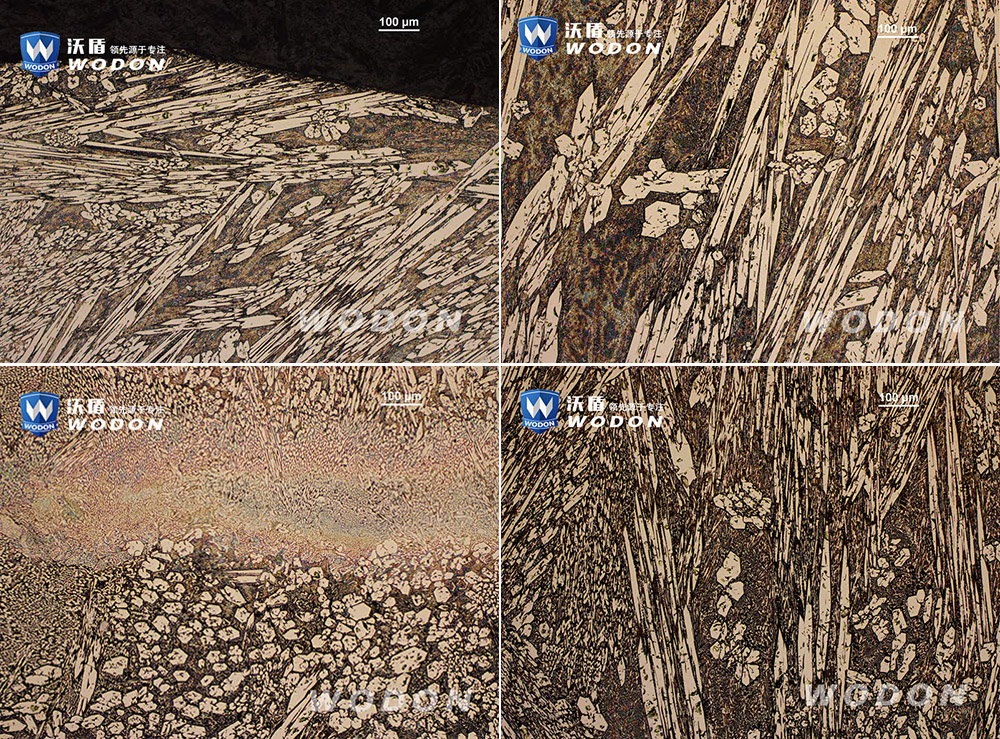

- He kiʻekiʻe ka nui o nā ʻāpana paʻakikī chromium carbide i ka papa ʻaʻahu. Hoʻokaʻawale ʻia kēia mau ʻāpana a puni ka papa, e hana ana i kahi microstructure ikaika. ʻO HRC 5 ka paʻakikī8~65a pili i ka mānoanoa o ka uhi.

- ʻO nā mea nui o ka pā Wodon he C (%): 3.0 ~6.0 a me Cr(%): 25~45. ʻO kēia ʻāpana kemika ka hopena i ka nui o nā mea paʻakikī Cr7C3 chrome carbide. ʻO ka micro-paʻakikī (a hiki i ka HV1800) o kēia mau ʻāpana a puni ka papa e hōʻoiaʻiʻo i kahi ʻili pale ʻoi loa.

- ʻO ka uhi a me ka papa kumu he mea hoʻopaʻa metala. E komo ka overlay i loko o ka pā kahua ma kahi o 0.8 ~ 1.8 mm, a hiki i 350 Mpa i kā mākou mau hoʻokolohua.

-

- WD1200 lole lolehiki ke hoʻohana no ka abrasion applica koʻikoʻitions.

- * ʻO Chromium carbide overlay ʻaʻahu i ka pā kūpaʻa

- * Ma ka ʻenehana hoʻoheheʻe ʻia arc

- * Hui Kemika: C: 3.0-6.0% Cr: 25-45%

- * ʻO Chromium carbide Cr7C3 ka hapa nui ma kahi o 50%

- * Hiki ke hiki i ka 50 mm ka mānoanoa o ka lole pale pale

- * Kūleʻa wela a hiki i 600°C

- * Lager maʻamau ʻaʻahu kūpaʻa wahi 1400*3000mm, 1400*3500mm, 2100*3500mm

- * ʻOi aku ka maikaʻi o ka palahalaha me ka ʻili maʻemaʻe

- * Oolea: HRC58-65(650-720HV)

- Hoʻohana nui ʻia kēia mau papa i ka Mining, Cement, Power, Coal, Port, Wind turbines a me Metallurgical..

-

Ka manawa hoʻouna: Sep-27-2021